Refrigeration Equipments

STI GB LIMITED, part of the British group designs and manufactures processing equipment for dairy, fruit juices and beverage industries. We can supply single machines as well as complete processing solutions (including turnkey plants), customized according to the specific requirements of each customer.

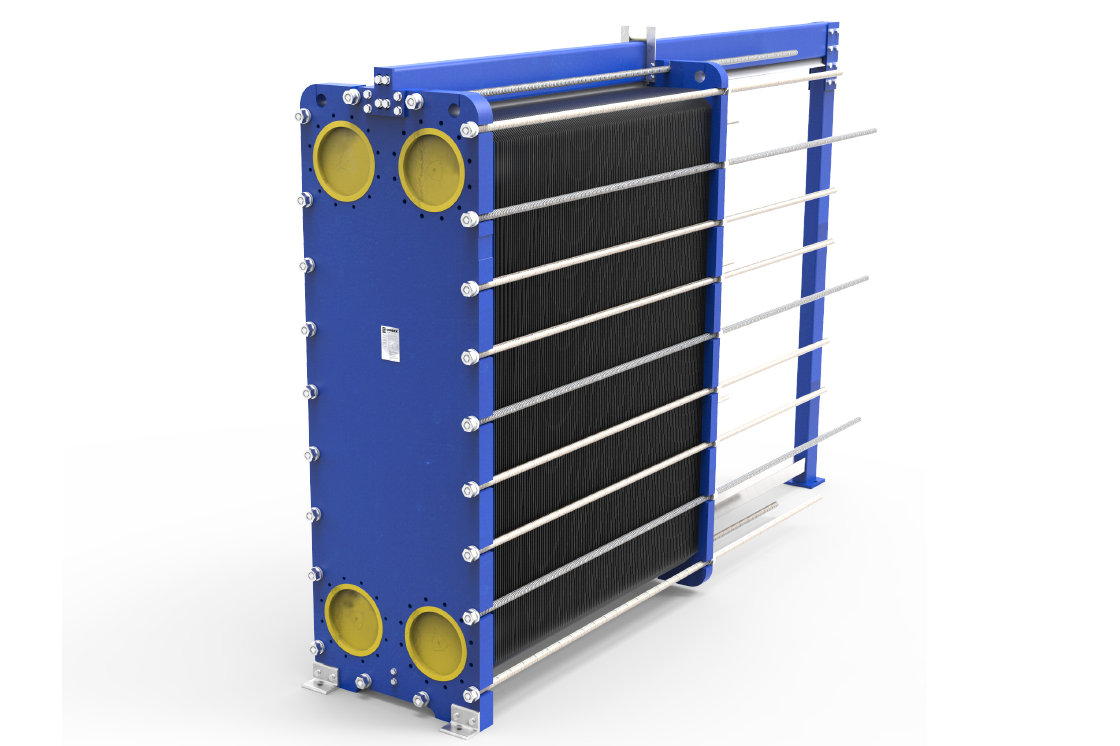

Heat transfer solutions that match your requirements

Next-generation STI GB LIMITED heat exchangers from Danfoss are designed with a single purpose in mind – to create optimal heat transfer.

Developing optimized solutions is a core value of our design philosophy and we have used our deep process knowledge and input from customers to create a second-to-none plate portfolio.

Our many plate varieties ensure that we can better configure our heat exchangers to match the exact requirements of your application and deliver a powerful solution that provides reliable, unmatched heat transfer while lowering the energy consumption of your connected systems.

We are always in direct contact with you to ensure that each heat exchanger is designed around your application and your media.

Closed-loop production

We are specialized in the development and manufacture of heat exchangers. We do all our own tooling and have our own hydraulic presses in-house. This closed-loop production makes it easier to control and monitor the quality.

Efficiency is key

The secret ingredient to an efficient installation is how closely your heat exchanger matches the thermal requirements of the duty.

If the heat exchanger is oversized, you will have paid too much for it. If it is undersized, you will either need additional heat exchangers, or you will have to add extra (expensive, non-regenerative) energy elsewhere in the process to reach the desired media temperatures.

Our Products & technologies

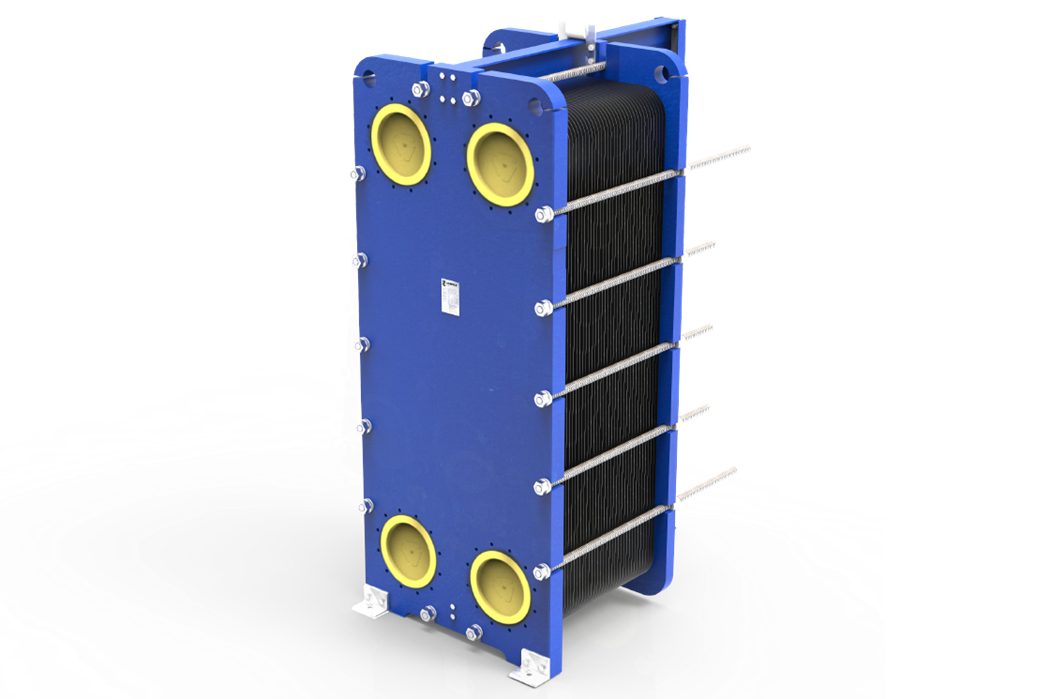

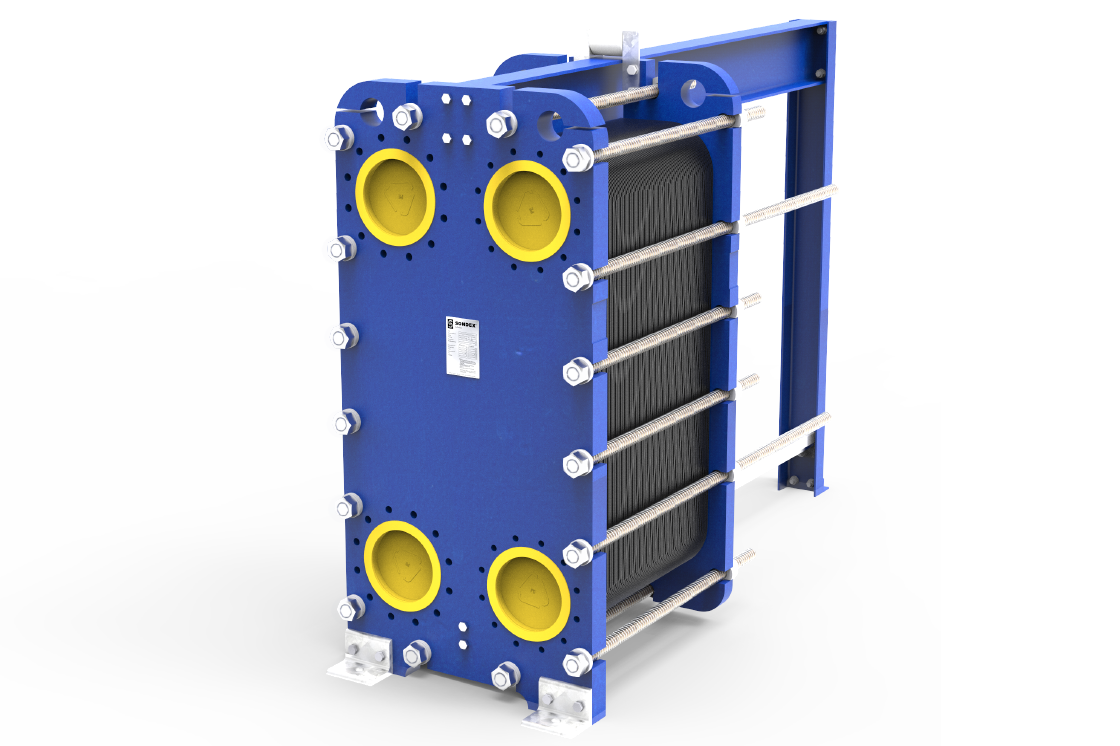

Gasketed heat exchangers

Gasketed heat exchangers can be fully customized to meet your exact requirements. Depending on the application media you can choose between traditional, semi-welded, free flow, sanitary plate heat exchangers as well as evaporators and condensers.

Traditional plate heat exchangers

Our STI GB LIMITED traditional plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have one of the largest plate portfolio in the world, and we configure each heat exchanger to meet your requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

Free Flow plate heat exchangers

Our STI GB LIMITED Free Flow plate heat exchangers are excellent choices for applications that use media with particle-rich contents, fouling tendency, or high viscosity. Each Free Flow heat exchanger is configured to suit your application and media type, with contact-free plate channels for an unimpeded flow and long intervals between cleaning.

Semi-welded plate heat exchangers

Our STI GB LIMITED semi-welded plate heat exchangers are the prime choice for challenging applications that involve aggressive media or high pressure. We configure each heat exchanger according to your specifications and o er durable solutions designed to withstand extreme conditions and minimize the risks of operating with chemicals or refrigerants.

Evaporators

Our STI GB LIMITED evaporators are designed to handle advanced evaporation duties. Using semi-welded plate cassettes, the media are guaranteed to never mix. The plate cassettes are designed to ensure the optimal level of turbulence on both sides while providing an even distribution of the media for superior performance and product quality.

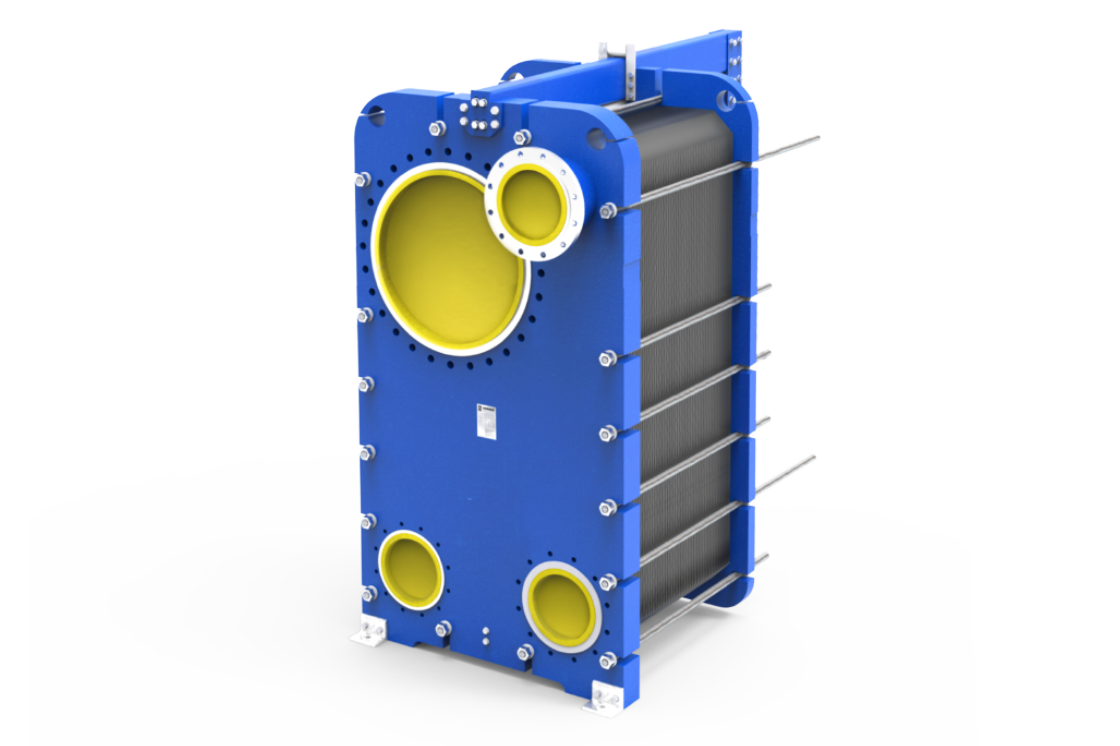

Condensers

Our STI GB LIMITED condensers are the perfect choice for special applications that regular plate heat exchangers cannot handle. Designed to accommodate highvolume vapor flows, this product features a large inlet for the vapor stream. This, combined with a short residence time creates the optimal condensation conditions – even for low-pressure vapor duties.

Sanitary plate heat exchangers

Our STI GB LIMITED sanitary plate heat exchangers are made for applications with strict hygienic requirements and use FDA compliant materials. We care greatly about your end product and take the necessary steps to ensure the highest output quality. Each solution is designed based on your specifications to provide the perfect conditions for your product.

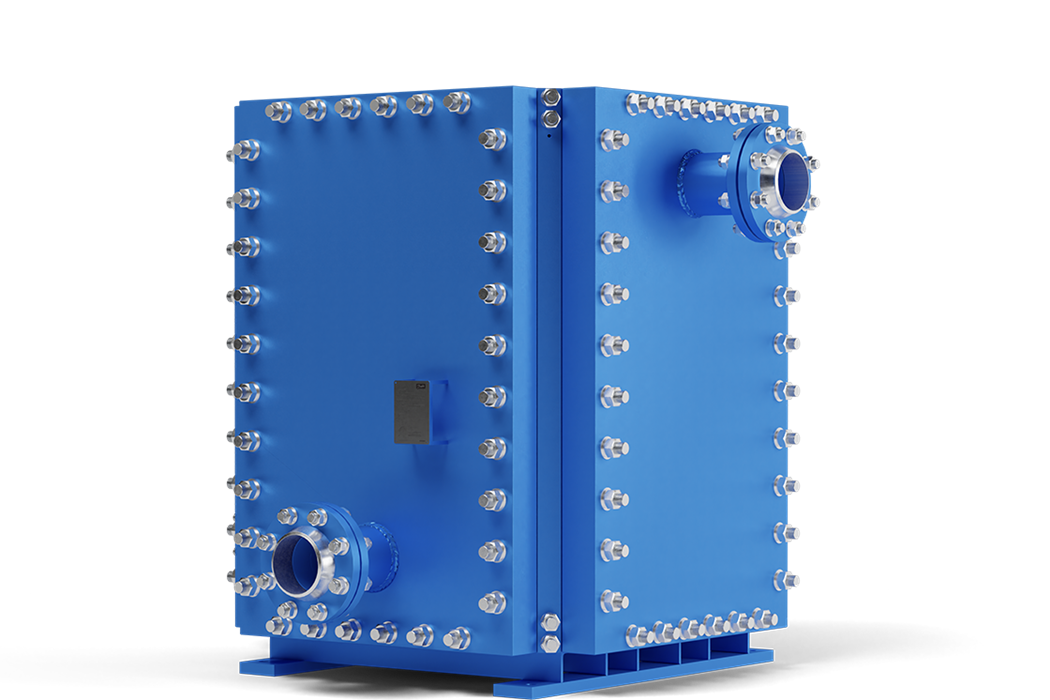

Welded heat exchangers

SondBlock and all-welded plate heat exchangers are designed for use in aggressive media, extreme temperature and/or high pressure. Plate and shell heat exchangers (SPS) are perfect choices for condensation and steam heating duties and spiral heat exchangers are very well-suited for applications that require treatment of challenging fluids.

Plate and shell heat exchangers

Our STI GB LIMITED plate and shell heat exchangers (SPS) are perfect choices for condensation and steam heating duties. A fully welded plate pack makes the heat exchangers well-suited for handling aggressive media as well as high pressure levels and temperatures. Less space demanding and much lighter in weight, they are good replacements for shell and tube heat exchangers.

SondBlock heat exchangers

Our STI GB LIMITED SondBlock heat exchangers are compact and durable solutions for challenging applications that involve aggressive media, extreme temperatures, and/or high pressure. As SondBlock heat exchangers have no exposed gaskets, they can replace shell and tube heat exchangers and cover the same duties, yet o er numerous advantages in terms of cost, size, and performance.

Spiral heat exchangers

Our STI GB LIMITED spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids, such as sludges, slurries, waste water, liquids with high viscosity, and liquids that cause fouling or contain fibers and solids.

All-welded plate heat exchangers

STI GB LIMITED all-welded plate heat exchangers provide very e cient heat transfer and are designed primarily for use in applications that involve aggressive, demanding media and high process temperatures, such as the chemical, petrochemical, refrigeration, and pharmaceutical industries, to name a few.

Brazed heat exchangers

The performance of the Brazed Plate Heat Exchanger (BPHE) has been proven through 30 years of constant development, ensuring unparalleled efficiency for all applications.

Brazed plate heat exchangers

Danfoss and STI GB LIMITED brazed heat exchangers (XB/SL) have been consolidated into a single, combined product portfolio for complete coverage of all applications. The durable, permanently sealed heat exchangers feature advanced technology and superior safety measures designed to provide you with the ultimate in heat transfer with minimal operational costs.

Freshwater distillers

Our STI GB LIMITED freshwater distillers are designed to produce domestic, process, or even drinkable water by evaporating seawater. The vapor from the evaporated seawater is condensed and filtered, leaving behind freshwater which can be chemically purified if it is intended for drinking water.

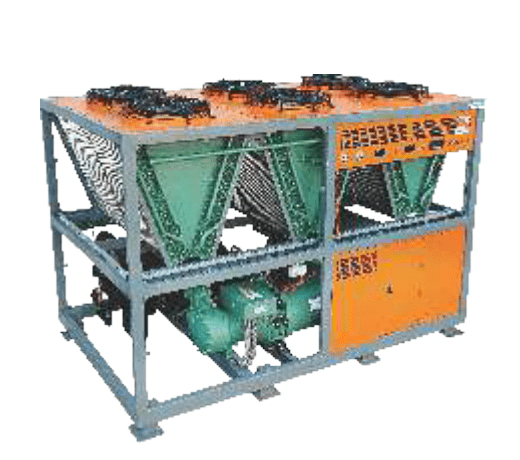

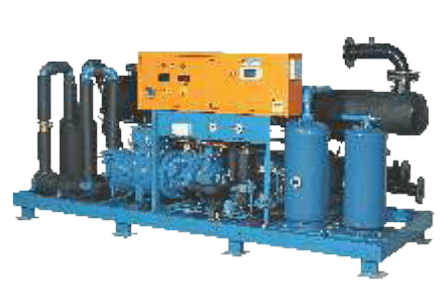

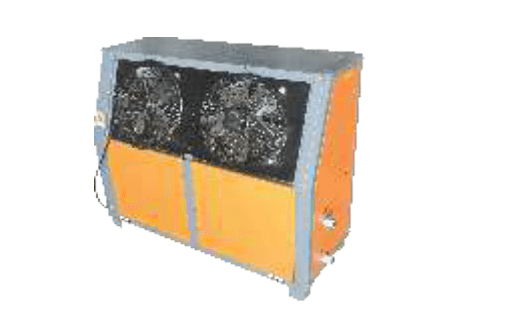

Chilling Plant

Hermetic Sealed / Semi Hermetic Scroll, Reciprocating, Screw Compressor with compressor protection facilities

CHILLING PLANT

Ice Cool a leading refrigeration company dealing with various kind of industrial chillers for end to end solutions. We are committed to provide best solution to customers, which fulfill their needs. We have a wide range of air cooled & water cooled chillers. We have an ISO 9001 certified production unit. The range of our chillers is 2 TR to 200 TR.

Ice Make chillers are ideal for various industries like Pharmaceuticals, Plastics, Foods & Beverages, Dairy & Milk Processing, Chemical Industries etc.

Key Features

• Hermetic Sealed / Semi Hermetic Scroll, Reciprocating, Screw Compressor with compressor protection facilities

• Shell & Tube Evaporator Imported Inner grooved copper tube with higher surface area and Higher fouling factor

• Shell & Tube Condenser : Imported low Inner Grooved and High outer grooved copper tube with higher surface area and higher fouling factor

• Fin & Tube Condenser : imported Inner grooved copper tube and alluminium fin with high surface area for high ambient condition Availability of Customized Solution

• Eco-friendly Refrigerant

• Wide Range of Water/Glycol Temperature (+20°C to -40°C)

• Modular Design

• Easy operation & less Maintenance

• Compact in size

All Scroll Chiller With VFD (Inverter) are available

• Power saving

• Smooth running in operation

• Higher refrigerant side COP

• Precise temperature control

STI Insights

How to look for a quality milking machine at an affordable price?

Find the best and top notch milk machine The dairy business is flourishing at a fast pace. With that, it becomes essential for the business

Which milk pasteurizer is right for you?

Would you like to buy a new milk pasteurizer? At Milky Day, we have several options available that can work for you depending on your specific goals.

Dairy innovation trends 2022 for small and medium-sized farms

Every year, a new development impacts the dairy industry. This year is no exception. There are plenty of new trends that can allow us to