Dairy, Food & Beverage

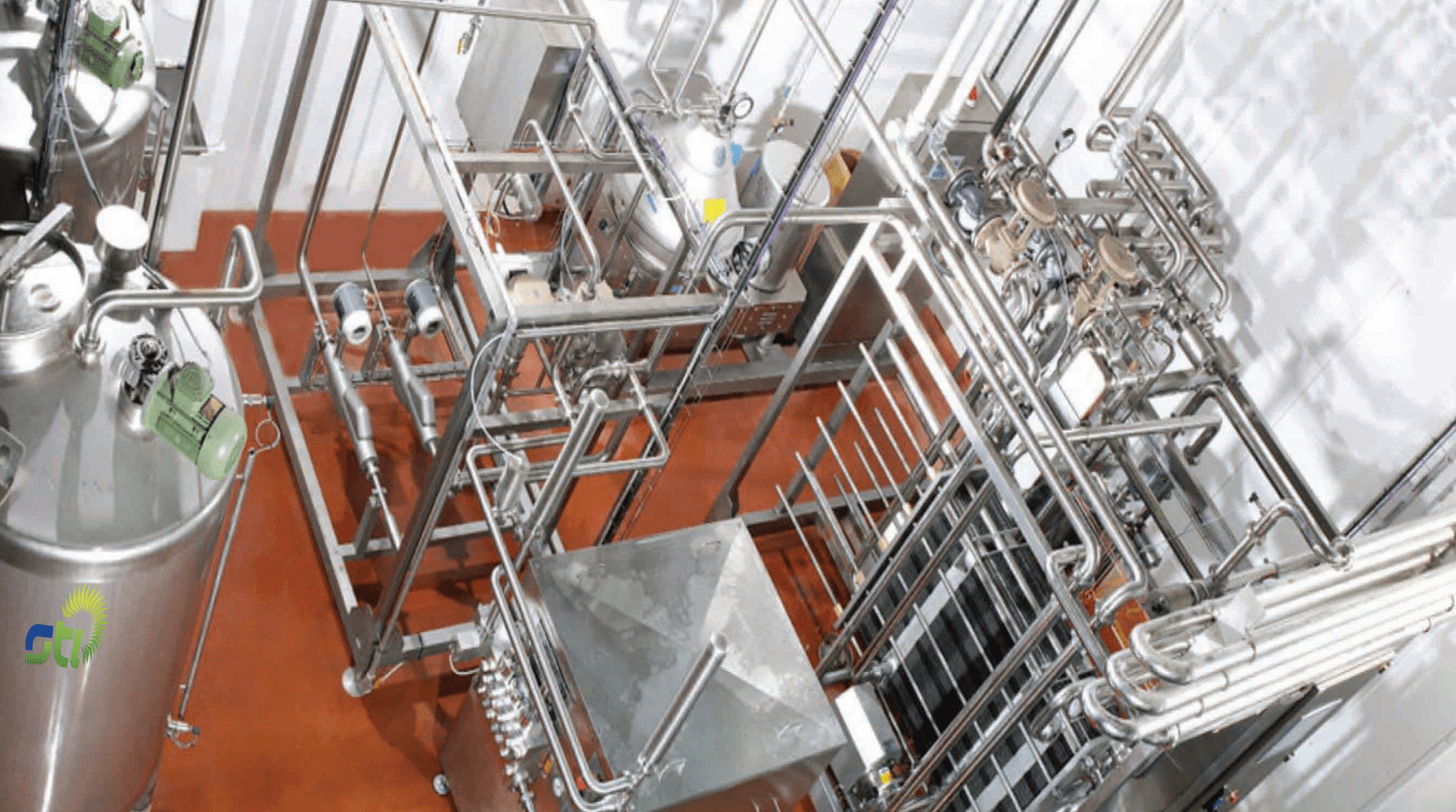

STI GB LIMITED, part of the British group designs and manufactures processing equipment for dairy, fruit juices and beverage industries. We can supply single machines as well as complete processing solutions (including turnkey plants), customized according to the specific requirements of each customer.

Dairy processing is a rapidly growing industry worldwide, driven by the increasing demand for milk and milk-based products from a continuously expanding population. At STI GB LIMITED, we have extensive experience and comprehensive knowledge in processing one of the world’s most essential and versatile foods.

Our global expertise sets us apart as we specialize in building large-scale facilities that meet the demands of the dairy processing industry, stay on top of new trends, and remain competitive. We provide complete plants, processing lines, and equipment for treating raw milk, manufacturing, filling, and packaging a wide range of milk and milk-based products, including butter, ice cream, yogurt, cheese, infant formula, milk powder, and whey and its derivatives.

At STI GB LIMITED, our expertise extends to project management, plant installation, commissioning, and after-sales service. All of our dairy processing technology is designed and engineered to meet strict hygiene, food safety, and quality standards, while operating efficiently and sustainably.”

Our Products & technologies

Milk Reception and Storage Machinery

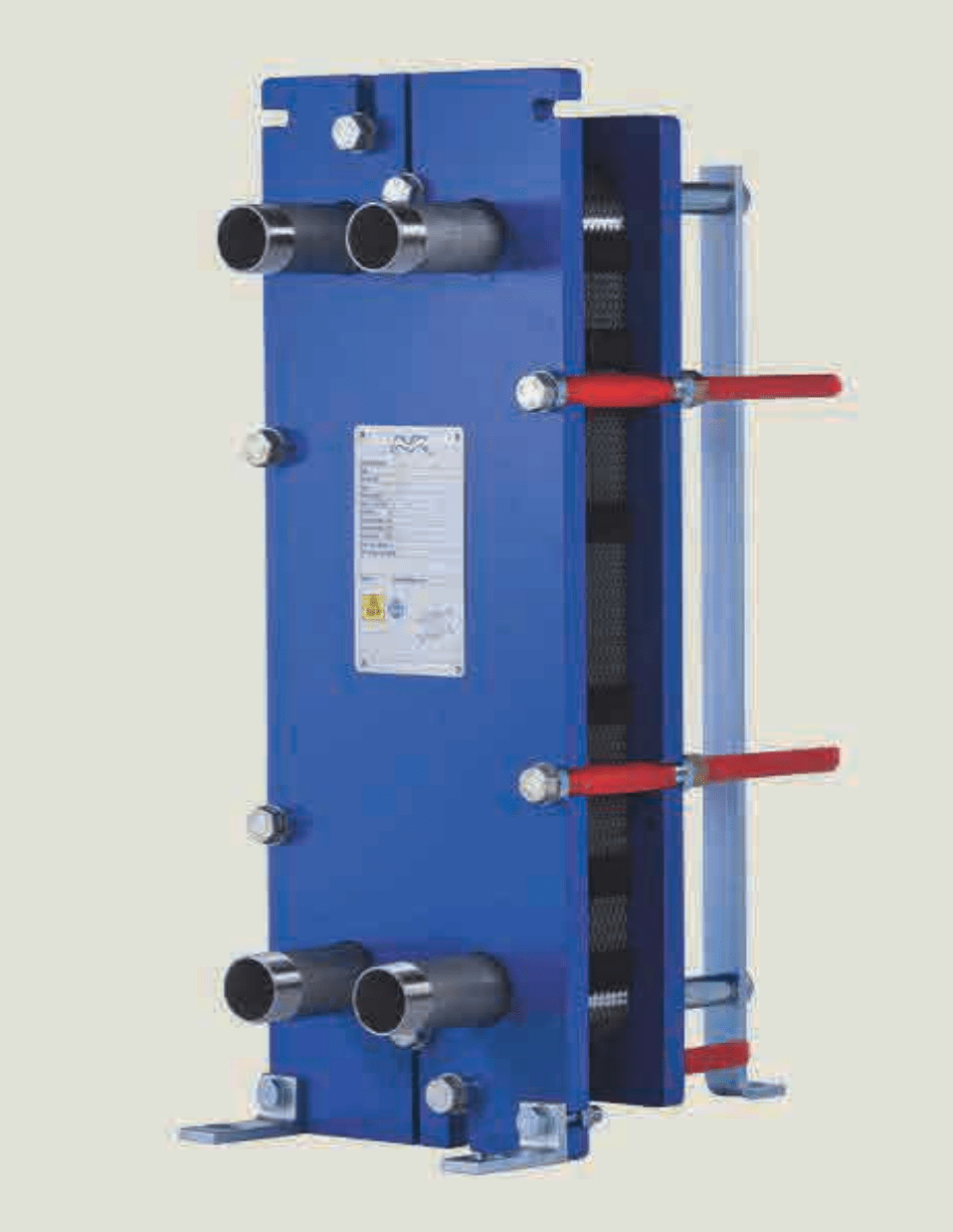

PLATE HEAT EXCHANGER

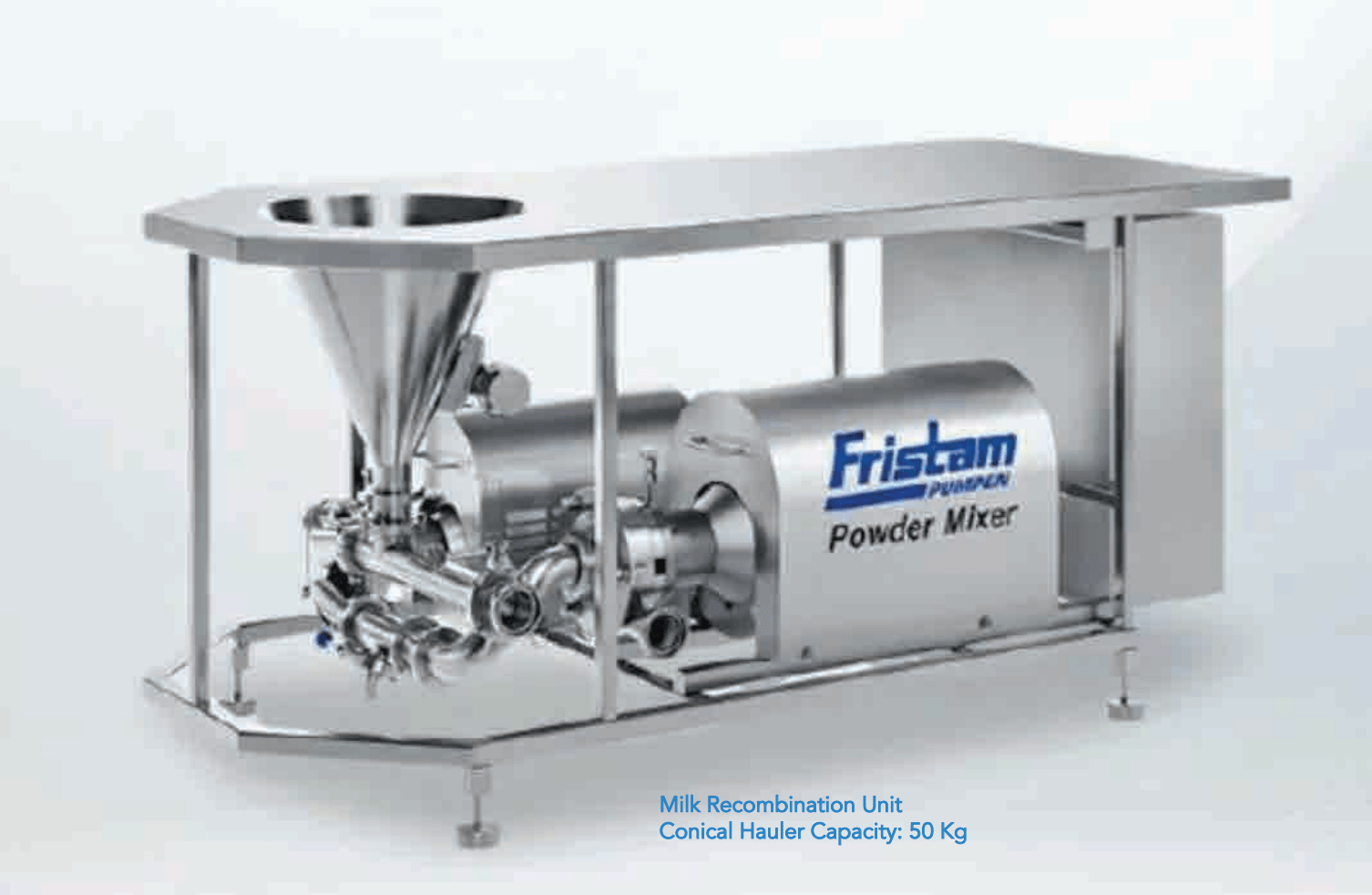

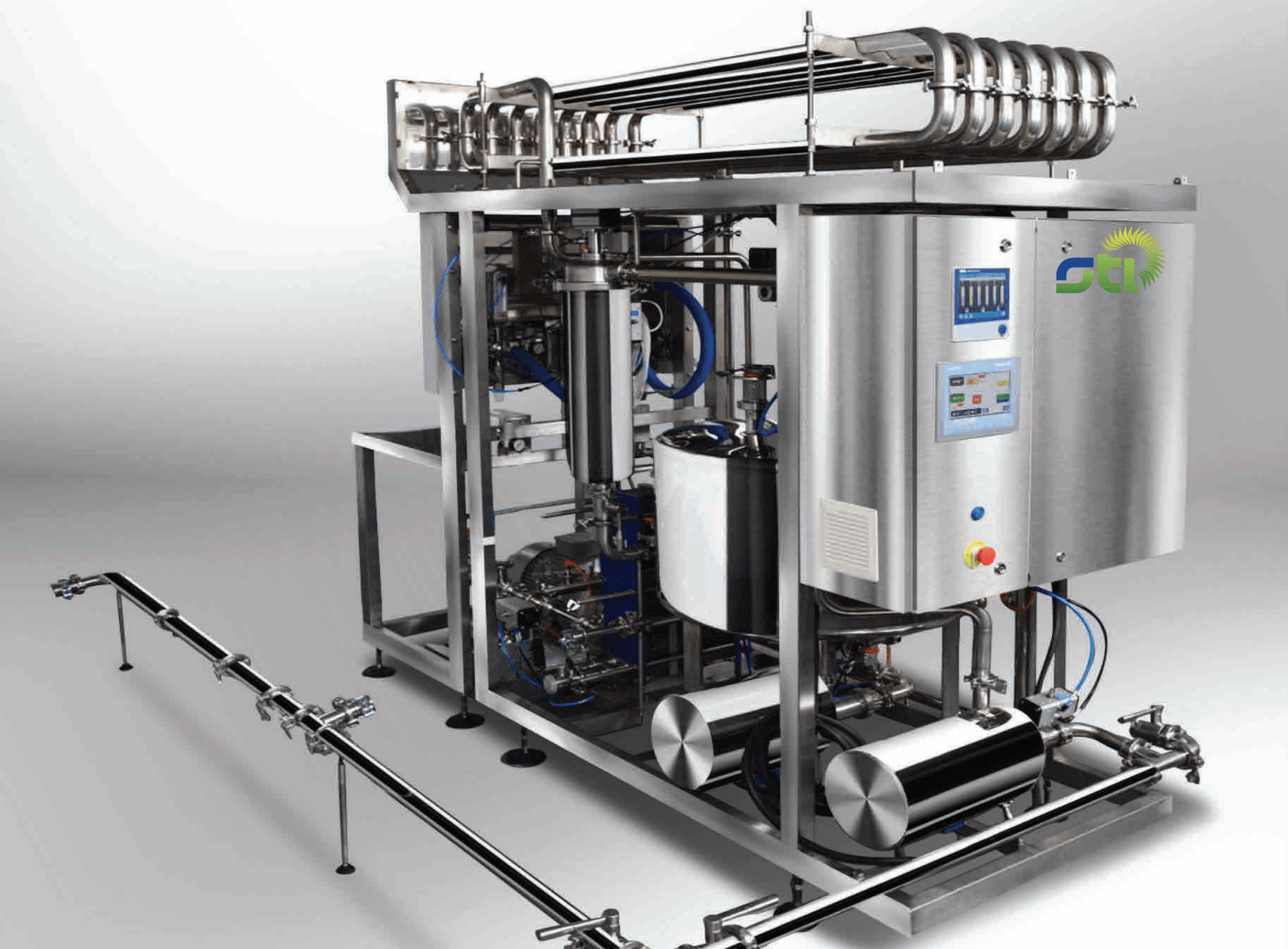

Milk recombination unit

MILK PASTEURIZATION PLANT

Complete Milk Pasteurization Unit

Float Control Balanced Tank

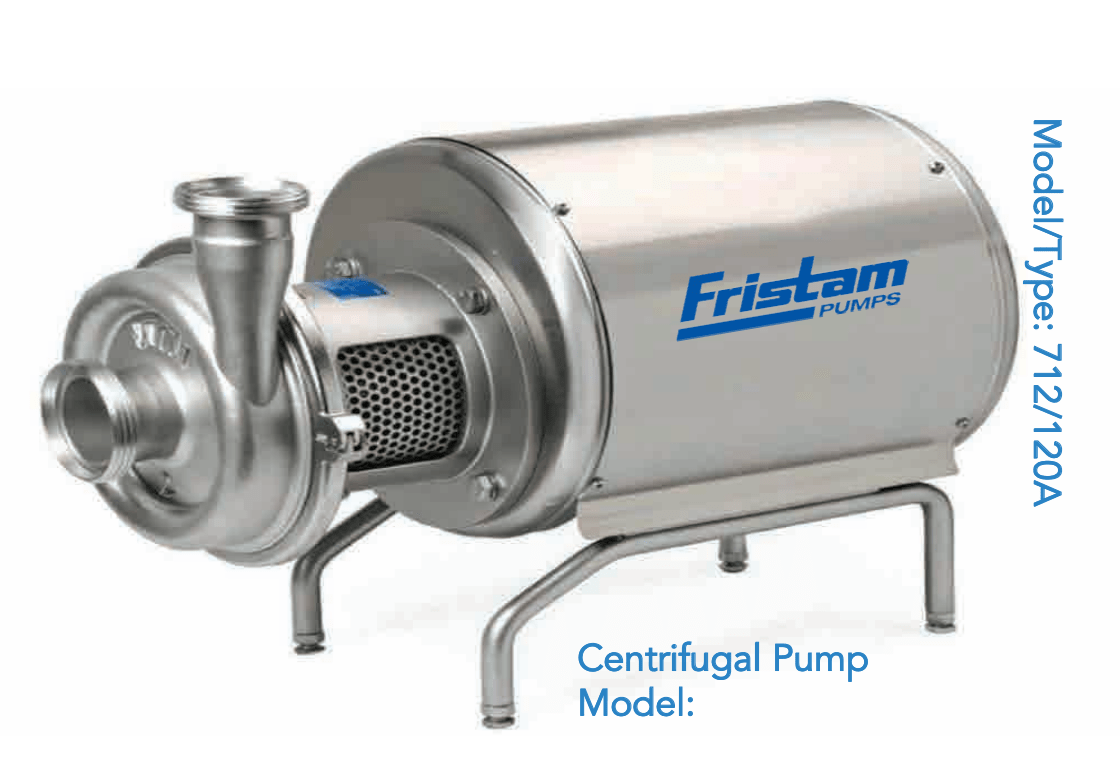

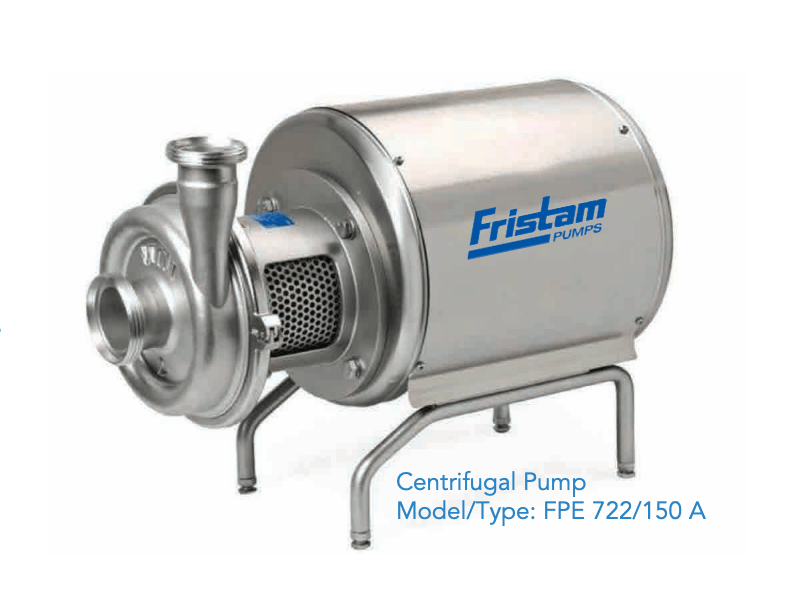

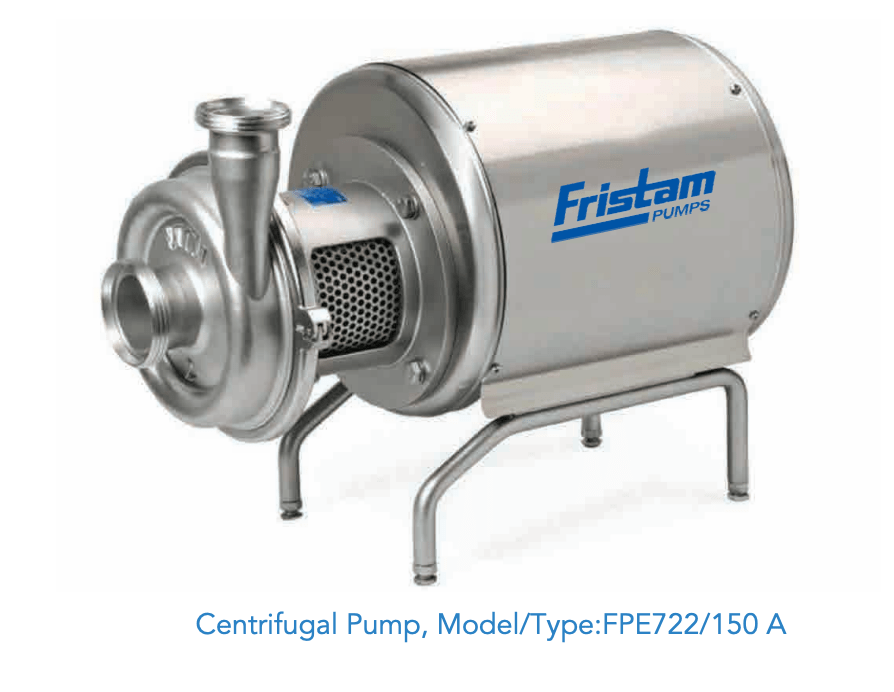

Centrifugal Pump, Model/Type:FPE722/150 A

Centrifugal Pump for hot water Circulation

Hot water equipment for PHE

Holding Tube and Electrical Control Panel

Deodorizer/Odor remover

CREAM SEPARATOR

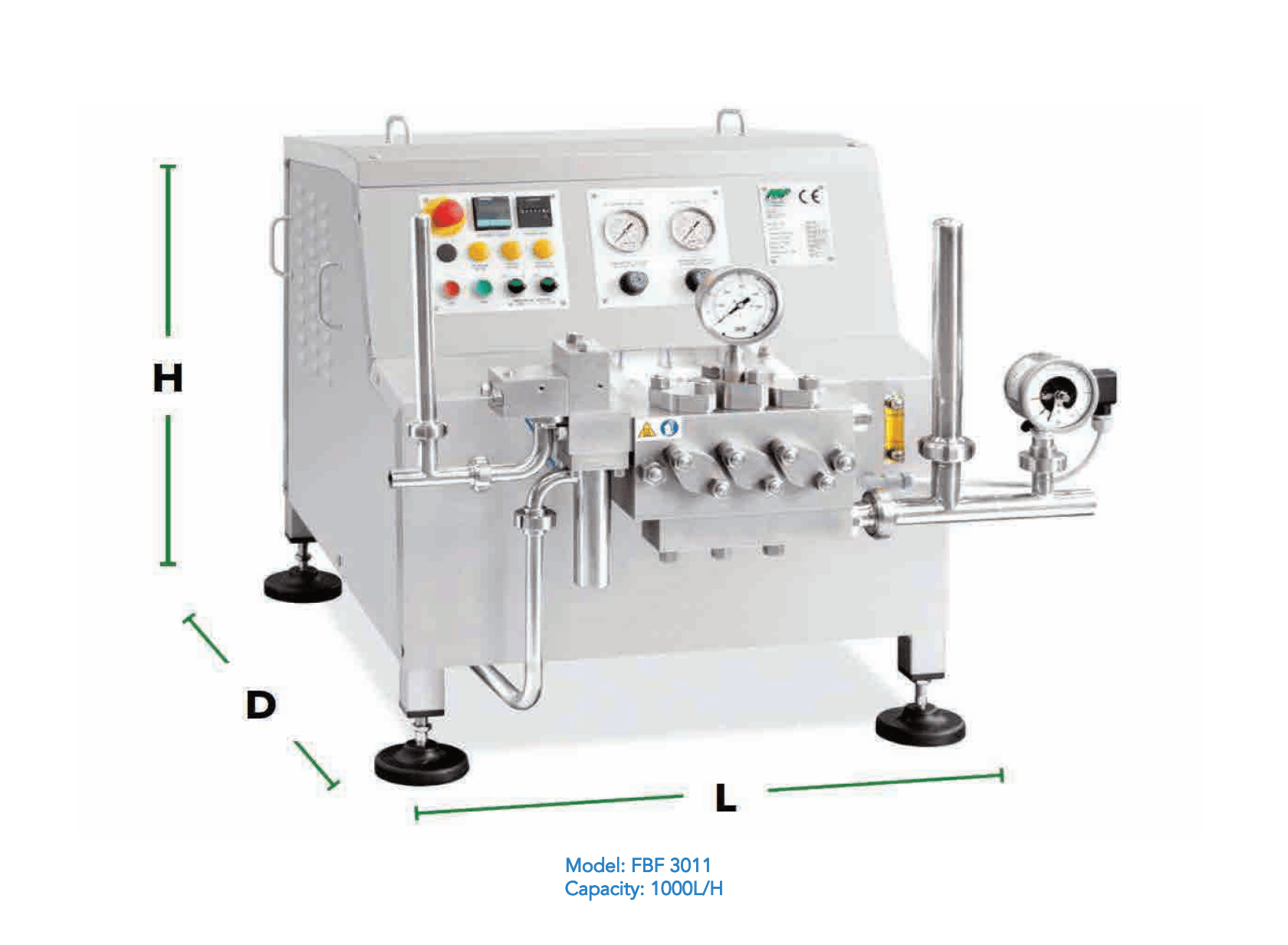

Homogenizer

Model: FBF 3011 Capacity: 1000L/H

Milk Transfer Pump, Cap. 5000 Lph

Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning. Sanitary type mechanical seal. Sanitary design, suitable for dairy industry. The pump is equipped with heavy duty motor, IP65, with suitable The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections. 380-400VAC, 50 Hz, 3 ph. (stabilized)

Milk Weighing Scale (digital) With Weighing Bowl

The weighing capacity of the unit is 0-600 kg.The unit is entirely manufactured of Stainless Steel AISI 304, assembled onto a sturdy main frame, suitable to support the weighing bowl. It is equipped with digital display (remote position) to indicate the quantity of milk measured (with printing option). The operator will manually fill the milk (from milk cans of 40 liters capacity) into the bowl unit.

Magnetic Inductive Flow Meter With Display - Capacity: 2000 Lph

Electromagnetic Flow Measuring System by Endress Hauser – Germany, complete with sensor and microprocessor-based transmitter. Cost effective flow measurement with a high degree of accuracy for a wide range of process conditions. Measurement accuracy ± 0.2%. The perfect solution for the milk counting at RAW MILK RECEPTION.

Milk Storage Tank, Cap. 1000 To 50000 Liters

No.4 supporting legs, obtained from bent stainless steel plate AISI304, equipped with adjustable feets. Manhole hatch Air vent type “oil bath” with special net anti-insect Total loading/discharge in the central part of the bottom. Bottom connection for the temperature sensor Washing sphere. Insulation of bottom and shell, thickness 65mm. external plates of finishing 20/10 AISI304 completely welded with satin finishing. The insulation will guarantee that when milk is stored at 4°C, the temperature will not rise more than 2°C in 24 hours. No.1 vertical stirrer (slow speed 35RPM), double paddle type with 6 stages, decentralized; centering bush on the bottom. Motor 1,5kW with servo-fan, covered by protection stainless steel carter.

Can Roller Conveyor

The roller shall be provided with ball bearings at either ends to take the load of milk cans. The conveyor shall be complete with frame made of mild steel duly painted resting on legs with adjustable mild steel ball feet.

BULK MILK CAN CONVEYOR CHAIN, MIN. 20 CANS

Conveyor chain for the transportation of milk cans (40 liters capacity). It is suitable for the transportation of 20 cans minimum per time. The conveyor is equipped with MOTOR driven gearbox, which will move the steel chain to transport the cans. The structure of the conveyor is made of hardened steel.

Milk Pasteurizer Complete With Cream Separator And Homogenizer

Any part which comes in contact with the product as well as all the main components are manufactured in stainless steel, properly finished, to ensure easy and accurate cleaning. Open type, single piece impeller ensuring high efficiency and low noise. Sanitary type mechanical seal.

No. 01 ELECTROMAGNETIC MILK FLOW METER Electromagnetic Flow Measuring System, complete with sensor and microprocessor-based transmitter. Cost-effective flow measurement with a high degree of accuracy for a wide range of process conditions. Measurement accuracy ± 0.5% .

MILK RECEIVING TANK

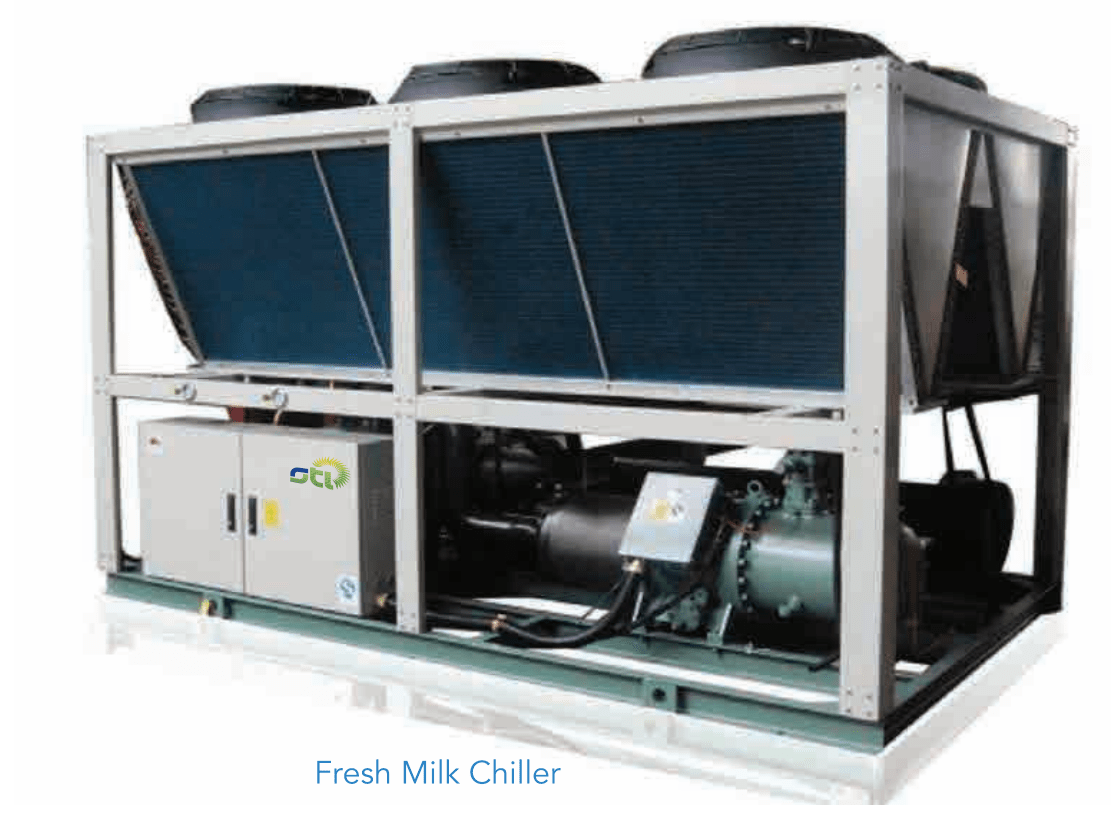

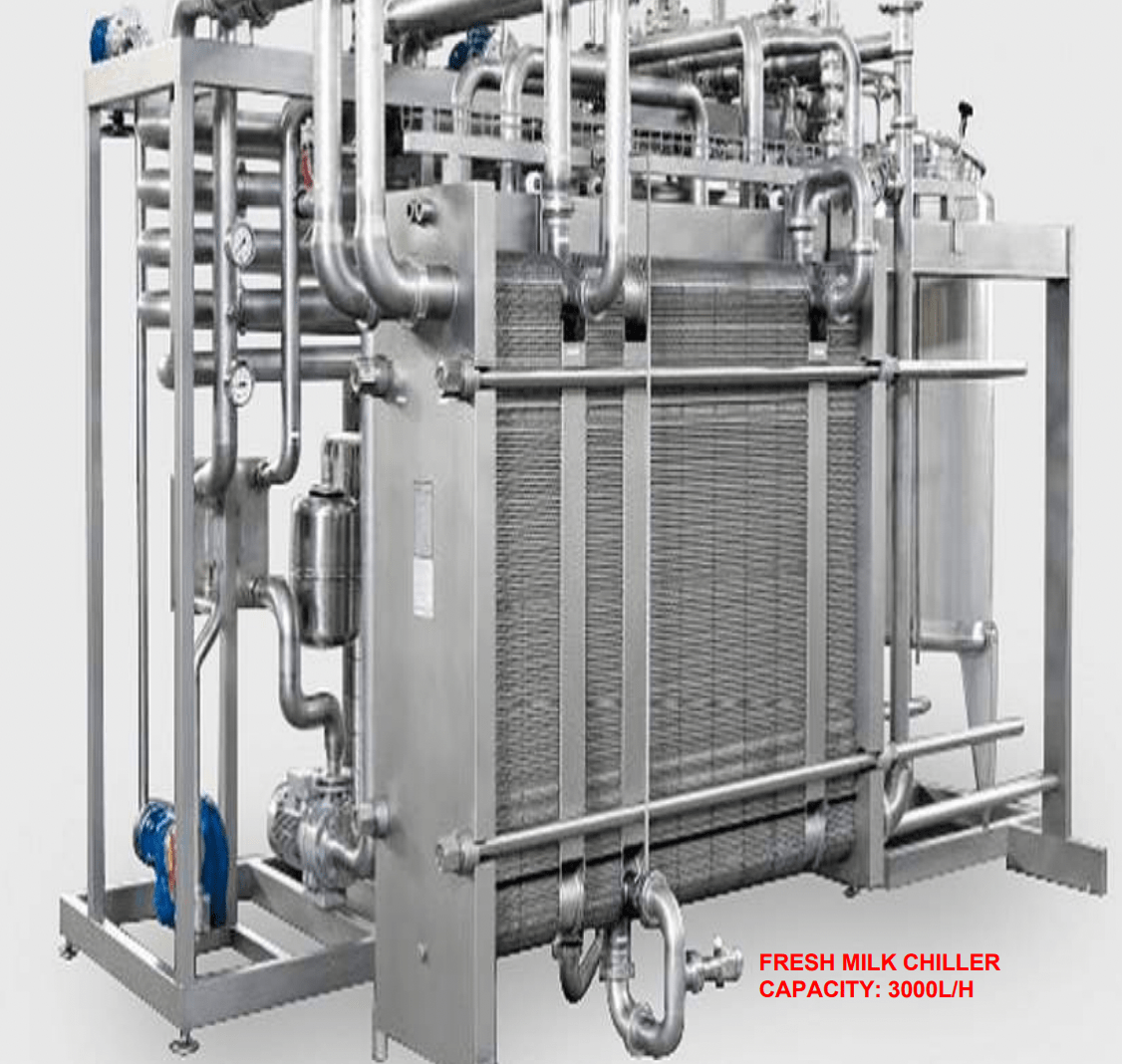

FRESH MILK CHILLER

MILK STORAGE TANK

MAGNETIC INDUCTIVE FLOW METER WITH DISPLAY

STORAGE TANK

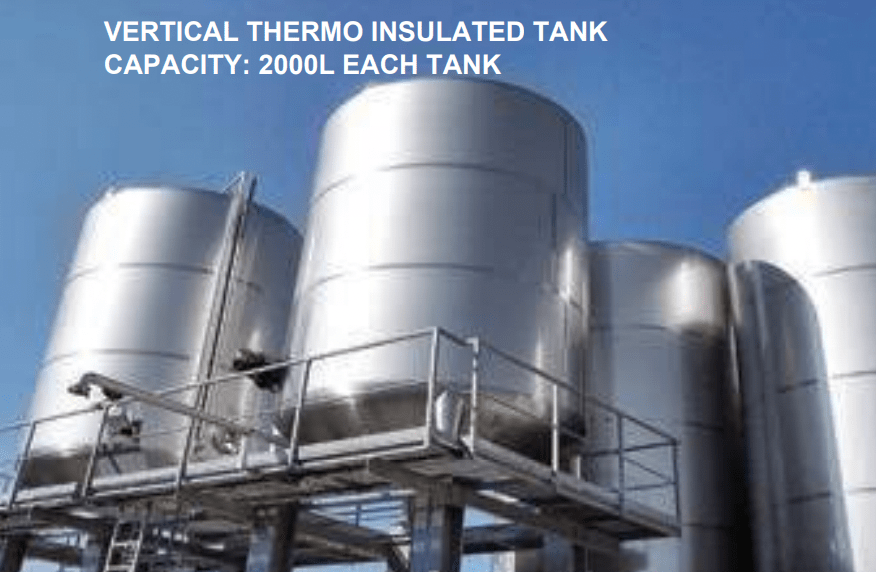

VERTICAL THERMO INSULATED TANK

MILK RECOBINATION UNIT

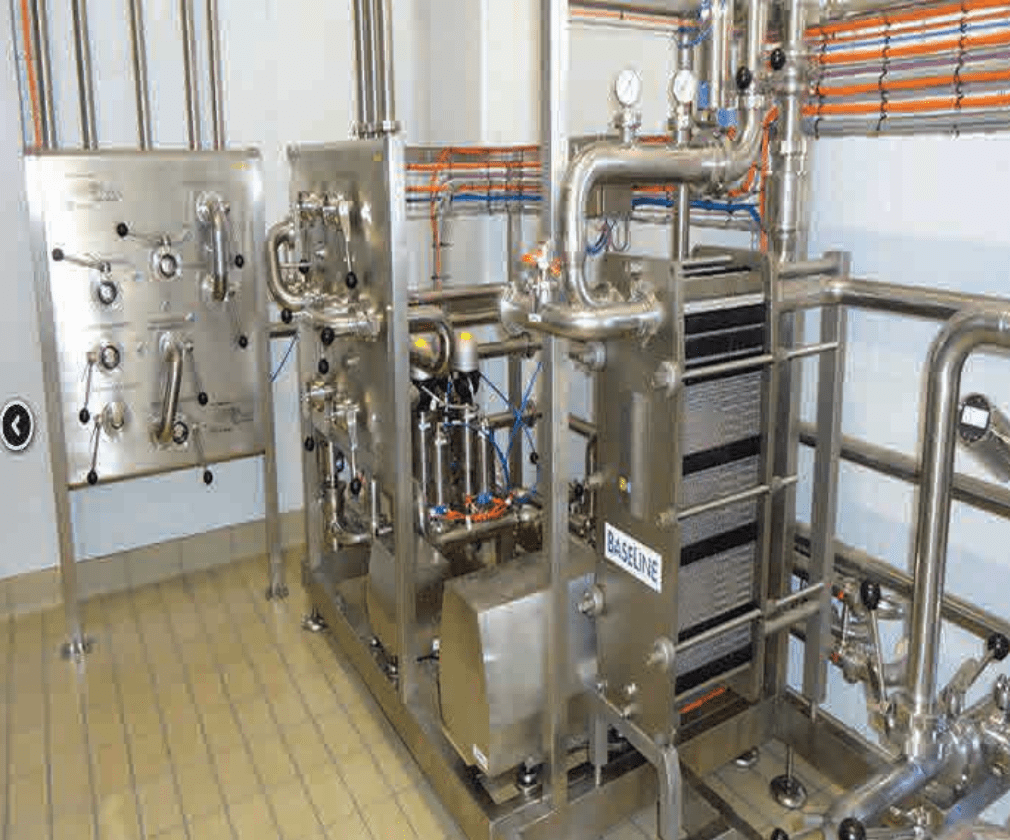

PASTEURIZE MILK PLANT

Achieving Confidence in Your Dairy Production

In the pursuit of higher quality and value-added dairy products, global producers often rely on trusted technology providers for processing support.

Developing new dairy products can be a significant investment of time and resources for many customers. The process involves complex formulations, detailed process designs, and plant validation, which can be daunting for customers to undertake alone.

At STI GB LIMITED, we understand these challenges, which is why we have dedicated test centers designed to help you confidently trial your products before scaling up production.

Our small-scale test plants offer critical process technologies, including separation, formulation, mixing, evaporation, and drying, allowing you to conveniently test your products and processes before making a large-scale investment. Working alongside our team of dedicated process experts, you can refine your recipes, formulate your products, and produce them at a small scale. We will then help you evaluate the final product properties and refine the process design before you scale up.

With decades of process experience gained from food processing plants worldwide, our test centers give you the confidence that the process units we deliver are optimized to suit local process and environmental conditions. The ongoing refinements we make through offline testing ultimately benefit the final solution for your production facility.

At STI GB LIMITED, we offer more than just process design. Our solutions encompass the latest technologies, equipment, and engineering expertise, which we combine to deliver your complete end-to-end solution, ensuring your peace of mind.

Download our

Dairy, Food & Beverage

Catalogue

STI Insights

How to look for a quality milking machine at an affordable price?

Find the best and top notch milk machine The dairy business is flourishing at a fast pace. With that, it becomes essential for the business

Which milk pasteurizer is right for you?

Would you like to buy a new milk pasteurizer? At Milky Day, we have several options available that can work for you depending on your specific goals.

Dairy innovation trends 2022 for small and medium-sized farms

Every year, a new development impacts the dairy industry. This year is no exception. There are plenty of new trends that can allow us to

a process engineering company

STI GB LIMITED, part of the British group designs and manufactures processing equipment for dairy, fruit juices and beverage industries. We can supply single machines as well as complete processing solutions (including turnkey plants), customized according to the specific requirements of each customer.