Home » Products » Dairy, Food & Beverage » Milk Cooling Tank

Milk Cooling Tank

STI GB LIMITED, part of the British group designs and manufactures processing equipment for dairy, fruit juices and beverage industries. We can supply single machines as well as complete processing solutions (including turnkey plants), customized according to the specific requirements of each customer.

Milk cooling tank with cooling unit

The tank, double walled with insulation, fixed/attached with stirrer, control panel, manual CIP and individual cooling unit (all mounted as a complete unit)

The tank, double walled with insulation, fixed/attached with stirrer, control panel, manual CIP and individual cooling unit (all mounted as a complete unit)

Every dairy farm is required to have a milk cooling tank. Immediately after the milk is derived from the livestock using the milking machinery it has to flow into a storage tank where its temperature needs to be lowered to and maintained at 4°C.

What is a milk cooling tank made of – A milk cooling tank, also known as a bulk milk cooler, consists of an inner and an outer tank, both made of high-quality stainless steel AISI 304.

Attached to the inner tank is a system of plates and pipes through which the refrigerant fluid/gas flows. The refrigerant withdraws heat from the tanks content (e.g. milk).

Capacity: 2000L

The milk receiving tank will be design to capable of cooling fresh milk from +36°C to below +4°C and maintain cooling temperature at +4°C, cooling unit mounted on same frame of the tank and each milk cooling tank has one cooling unit individually.

Every cooling tank come with a condensing unit which circulates the refrigerant and conveys the withdrawn heat to the air. The space between the outer tank and the inner tank is isolated with polyurethane foam. In case of a power failure and an outside temperature of +36° C, the content of the tank will warm up only +1°C in 24 hours. To sacilitate an adequate and rapid cooling of the entire content of a tank, every tank is equipped with at least one agitator. Stirring the milk ensures that all milk inside the tank is of the same temperature and that the milk maintains homogene.

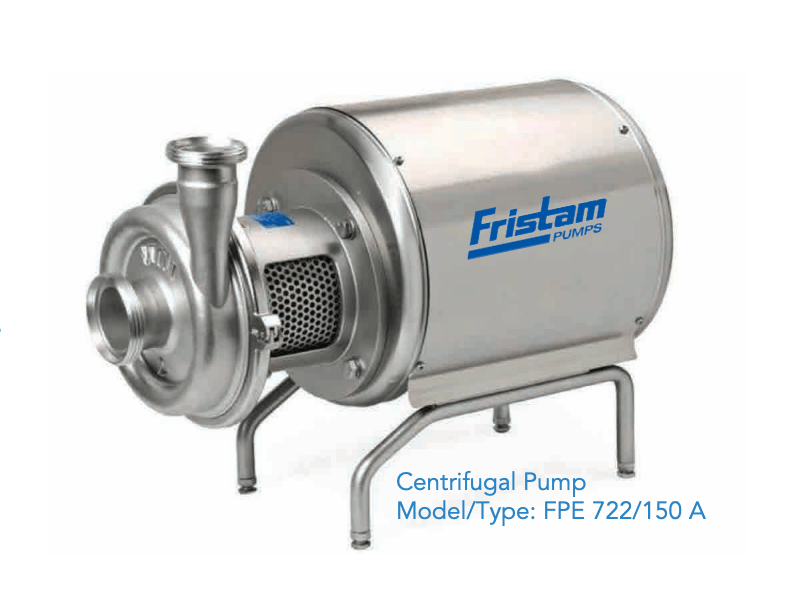

Centrifugal Pump

Centrifugal pump (for transfer of fresh milk from milk cooling tank to balance tank)

Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.

– Sanitary type mechanical seal.

– Sanitary design, suitable for dairy industry

– The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections. 380-400VAC, 50 Hz, 3 ph. (stabilized)

– Capacity:1000L

– Make/Brand: FRISTAM

– Model/Type: FPE722/150 A

– Country of origin: GERMANY

Electric control panel for suitable operation of milk cooling tank.

Download Complete Dairy Solution Brochure PDF

CONTACT US

- +44 1438316518

- +44789240418

- [email protected]