Home » Products » Dairy, Food & Beverage » Milk Reception and Storage Machinery

Milk Reception and Storage Machinery

STI GB LIMITED, part of the British group designs and manufactures processing equipment for dairy, fruit juices and beverage industries. We can supply single machines as well as complete processing solutions (including turnkey plants), customized according to the specific requirements of each customer.

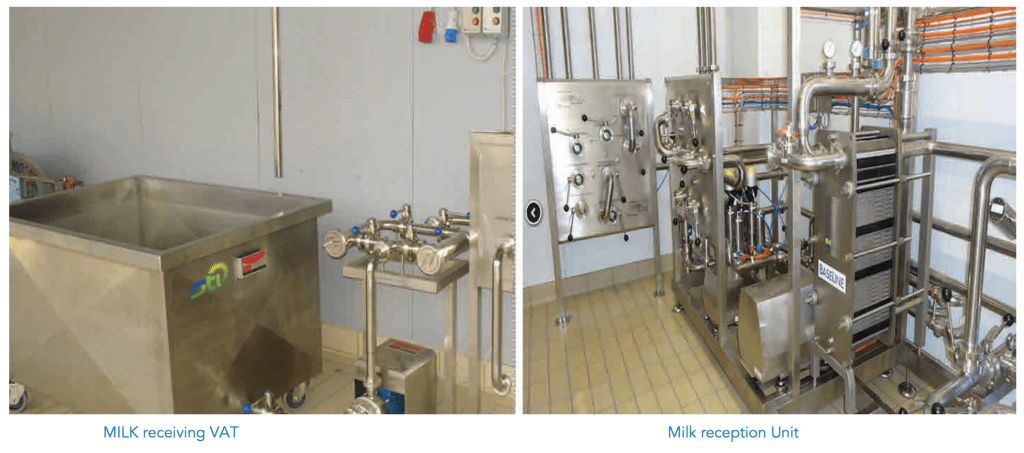

MILK RECEPTION UNIT

Automatic Milk Reception

Milk reception unit means the whole tanks and units which provide necessary filtering and weighing of the milk that comes from dairies to processing plants with milk carrier tankers. They work as digital counters.

This process is done because of collected milk can not come to the collecting centre in the same temperature from different farms and producers. Milk is collected from different dairies and farms with different temperatures and ingredients. Firstly this milk is controlled in milk collecting centers, it is cooled in cooling tanks with 4 degrees after determined. The milk which is necessarily controlled and ready in cooling tank in 4 degrees, is delivered to processing plants with insulated carrier tankers and milk cans. Milk should be delivered to this places approximately in 6 hours, because these tankers also have a certain time for insulation. And lastly, milk is transferred from tankers to receiving units with the help of a milk self priming pump.

Milk receiving unit has two different kinds, they are automatic ones and manualones;

Automatic Milk Reception Unit:

Automatic milk reception units take the milk from milk carrier tanks with the help of self priming pumpand manually XXXX then makes filtering and get the surplus air and foam out frommilk with a stainless steelbuoy. This system helps flow meter to doits mission more effectiveand the milk amount, cominginto the plant. The milk is ready tobeprocessed.It can be pulled intoprocessing line in which the milk will be used.

Manual Milk Reception Unit:

Manual milk reception unit as understood from its name isasystem operations are done manually.In this units youcan use fill-empty system.

Milk receiving vat unit comprising following accessories:

- Milk receiving vat with sloped bottom and lid/cover including arrangement for connections with centrifugal pump.

- The unit is entirely manufactured of Stainless Steel AISI 304 assemble onto a sturdy mail frame suitable to support the weighing bowl

- Capacity of the VAT: 1000L.

Self Priming Pump/ Vacuum Pump:

Automatic Milk Reception

Self-priming pump/vacuum pump including necessary connections with milk couplings and milk tubes/pipes (transfer/suction of milk from milk bowser or milk cans to receiving vat)

- Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.

- Sanitary type mechanical seal.

- Sanitary design, suitable for dairy industry-

- The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections. 380-400VAC, 50 Hz, 3 ph. (stabilized)

- Capacity: 10000L/H

- Make/Brand: FRISTAM

- Model/Type:FZ 20 A

- Origin: Germany

Centrifugal Pump

Centrifugal pump with inline filter & manual/mechanical flow control valve and flow meter (for transfer of milk from receiving vat to milk plate cooler)

- Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.Sanitary type mechanical seal.

Sanitary design, suitable for dairy industry - The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections. 380-400VAC, 50 Hz, 3 ph. (stabilized)

- Capacity: 10000L/H

- Make/Brand: FRISTAM

- Model/Type: FPZ 712/120A

- Country of origin: GERMANY

Connection pipe or hose pipe (for transfer of milk from milk cooling tank of milking parlour to milk receiving vat of dairy plant) (Quantity – 100 Meter maximum.

TANKER/MILK COOLING TANK UNLOADING PUMP GROUP WITH FOOD GRADE HOSE PIPE

Capacity of the pump: 10000 litres/hour

Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.

Sanitary type mechanical seal.

Sanitary design, suitable for dairy industry The pump is assembled onto a proper TROLLEY which is

equipped with wheels for an easy handling of the pump. The trolley is made of STAINLESS STEEL AISI 304.

– The Group is also equipped with:

– Small electrical cabinet for the easy control of the pump

– Flexible hose, food grade type, 20 meters long

Milk Dump Tank

Insulated milk dump tank is designed along/in between milk receiving vat and milk plate cooler

TECHNICAL FEATURES:

- Entirely manufactured of Stainless Steel AISI 304

- Open top, horizontal type tank, with rectangular design.

- Useful capacity is 1000 liters

- The dump tank is correctly positioned under the milk weighing bowl in order to collect the milk.

- It is made with minimum 2mm thickness Stainless

- Steel, AISI 304. The tank is also equipped with:

- Proper sloped bottom

- Outlet fitting with 2″ male part

- Adjustable feet

- Capacity: 1000L

- Make/Brand: EASY

- Model/Type: EZY 10

- Country of origin: UNITED KINGDOM

Download Complete Dairy Solution Brochure PDF

CONTACT US

- +44 1438316518

- +44789240418

- [email protected]