Home » Products » Dairy, Food & Beverage » MILK PASTEURIZATION PLANT

MILK PASTEURIZATION PLANT

STI GB LIMITED, part of the British group designs and manufactures processing equipment for dairy, fruit juices and beverage industries. We can supply single machines as well as complete processing solutions (including turnkey plants), customized according to the specific requirements of each customer.

Complete Milk Pasteurization Unit

MILK PASTEURIZER COMPLETE WITH CREAM SEPARATOR

Milk pasteurizing unit complete Plate Heat Exchanger (PHE) with heating at 95°C. and chilling water at 1°C to 2°C capacity minimum 1,000 L/H, the PHE will be designed for processing of fresh milk/recombined milk at normal temperature, complete pasteurizer unit built on a frame with the components of float controlled balance tank, milk pump, flow control valve, cream separator, homogenizer, registration unit for digital registration of pasteurization temperature (PLC controlled) position of flow divert valve, PHE double safety plates, divert valve, duration holder, hot water section for heating with steam and complete steam set – valve, reduction valve, regulation valve etc

Milk Pasteurization Plant

Capacity 1000L/H

PLATE HEAT EXCHANGER

TECHNICAL FEATURES

Product to be processed MILK

– Capacity : 1000 l/h

– Plates manufacturer ALFA LAVAL, SWEEDEN

– Plates material STAINLESS STEEL AISI 316

– Design : SANITARY

– Gaskets material/type NBR/Loc-in type (no glue)

– Plate Thickness 0,6mm

– ΔΤ..: MAX 2°C

– THERMALRECOVERY: >80%

CONSTRUCTIONDETAILSOFPLATEHEATEXCHANGER

– FRAME AND PRESSING PLATE are stainless steel plated, lapped, and provided with female unions.

– UPPER AND LOWER BARS are made of stainless steel. The upper bar is provided with suitable plates centering system.

– INTERMEDIATE PLATES (for plate heat exchangers with more than one section) are made of stainless steel, lapped, and provided with female unions.

– TIE RODS AND NUTS are manufactured in high resistance stainless steel and the nuts are provided with antiseizing bush.

– PLATES are suitable for milk processing. They are designed to ensure the highest heat transfer with low pressure drop.

– THE GASKETS are suitable for food industry and resistant to chemical agents contained in the washing solutions. They are “lock-in” type (no glue needed).

– INLET and outlets: SMS unions, Stainless Steel 304

– the unit is equipped with temperature indicator (thermometer) on inlets and outlets

Essential tool such as the operating wrench is supplied.

– The unit is equipped on adjustable feet.

Float Control Balanced Tank

Capacity minimum 100 L

Composition Of The Pasteurizer

No. 01 FLOAT BALANCE TANK

Entirely manufactured with STAINLESS STEEL AISI 304, capacity 100 litres, equipped with:

• level control

• milk inlet valve

• water inlet valve

• Washing sphere

• Hermetic cover

• Hermetic cover

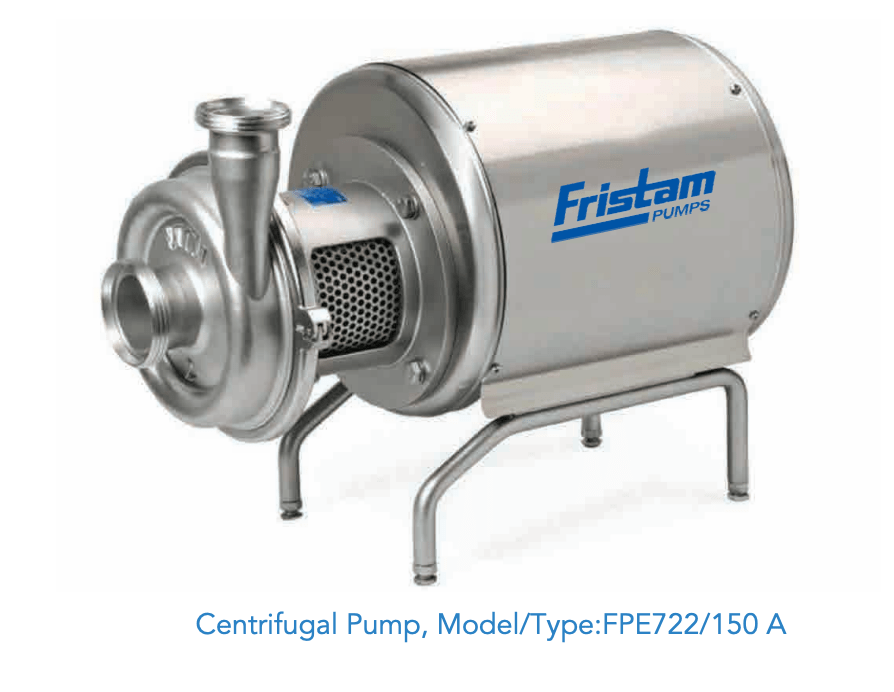

Centrifugal Pump

Model/Type:FPE722/150 A

Centrifugal pump, magnetic inductive flow meter milk inline filter & manual flow control valve for transfer of milk from balance tank to pasteurizer

Any part which comes in contact with the product as well as all the main components are STAINLESS manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.

– Sanitary type mechanical seal.

– Sanitary design, suitable for dairy industry

– The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections. 380-400VAC, 50 Hz, 3 ph. (stabilized)

– Capacity: 1000L/H

– Make/Brand: FRISTAM

– Model/Type: FPE 722/150 A

– Country of origin: GERMANY

Centrifugal Pump for hot water Circulation

Hot Water Circulation Pump. Model/Type: FPE 722/150 A

– Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.

– Sanitary type mechanical seal.

– Sanitary design, suitable for dairy industry

– The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections. 380-400VAC, 50 Hz, 3 ph. (stabilized)

– Capacity: 2000L/H

– Make/Brand: FRISTAM

– Model/Type: FPE 722/150 A

– Country of origin: GERMANY

Hot water equipment for PHE

Hot water equipment for PHE (generally in the same execution as PHE, steam/water exchanger/expansion tank)

No. 01 HOT WATER PRODUCING/CIRCULATING SET FOR PASTEURISING TEMPERATURE

FEEDING PRESSURE: 3 bar, stabilised.

Composed of:

– Steam ON/OFF valve

– Steam filter

– Steam modulating valve

– Hermetic, Brazed welded type plate heat exchanger with security cover

Float steam trap.

HOT WATER CIRCULATING CENTRIFUGAL PUMP

– Safety and control accessories such as thermometer, dial pressure gauge, air valve, safety valve, expansion tank, automatic water filling system

– Piping and connections between all the above parts.

Milk Pasteurization plant

Holding Tube and Electrical Control Panel

Holding cell/tubular holder for plate heat exchanger, 30 seconds holding time for pasteurizing milk as required

No. 01 TUBOLAR HOLDER

HOLDING TIME: 30 seconds (or different, must be confirmed before order)

Capacity: 1000 liters/hour

STAINLESS STEEL EXECUTION; INSPECTABLE. THE TUBULAR HOLDER TOTALLY WELDED AND IT IS SUPPORTED BY A SUITABLE STAINLESS-STEEL FRAME.

Flow splitter/flow reverse valve or divert valve, rotary alarm, automatic operation in case of temperature failure, the flow will be returned to the balance tank (for recombination, receiving, reserve/filling, pasteurization & CIP section)

No. 01 FLOW PNEUMATIC DEVIATION VALVE (MILK DIVERSION) By a 3-ways pneumatic valve, it diverts the flow of the product back to the balance tank in case of anything wrong pasteurization temperature or pressure or above description.

Electrical Control Panel:

Electric control panel comprising flow diversion valve, flashing rotary warning lamp, regulation valve for steam, temperature regulator and air supply/regulator which will be PLC controlled unit with programmers for startup/stabilizing, product pasteurization and cleaning.

No. 01 PLC complete with TOUCH SCREEN for the control of all process phases and for the constant monitoring of: Pasteurisation temperature by means of PT100 sensor. It is equipped with suitable electro pneumatic converter for the hot water modulating valve command.

differential pressure in each recovery section of the plate heat exchanger by means of piezo resistive sensors. It is equipped with suitable electro pneumatic converter for the counter pressure valve command.

outlet temperature by means of PT100 sensor. It is equipped with suitable electro pneumatic converter for the hot water modulating valve.command.

No. 01 ELECTRONIC RECORDER, for the automatic Recording of the main processing parameters, that are:

* Pasteurising temperature

* Product outlet temperature

* Differential pressure

* Activation of flow deviation valve

PNEUMATIC BOARD, COMPLETE WITH:

– SET OF ELECTRO VALVES

– Compressed air FILTER-REDUCTION device

No. 01 STAINLESS STEEL FRAME

Including the assembly, onto the same, of all the above described equipment and of the control panel. Piping and electric connections between all the components of the pasteurising unit + centrifugal separator are also included.

Deodorizer/Odor remover

Deodorizer/Odor remover along with pasteurizing unit STAINLESS STEEL AIR SEPARATOR (MILK DEAERATOR)

Capacity: 1000 liters/hour

The unit is composed of:

– Stainless Steel Closed Tank

– level probe

– vacuum pump complete with electrovalve and pressure gauge

– safety tank

– vacuum gauge

– The unit is electronically controlled and connected to the main Electrical panel of the Milk reception group.

– Capacity: 1000L

– Make/Brand: STI

– Model/Type: EASY

– Country of origin: UK

CREAM SEPARATOR

Mora Marco milk separators of the open type series are specially designed to skim, standardize and clarify milk, cream and whey. These separators are studied and manufactured to permit very high rotation speed of the bowl and to obtain the best separation efficiency of solid/heavy parts with very small diameters (fat, dirty, spore and bacteria, etc.). Product feeding comes under pressure by a soft inflow system and is accelerated to separation speed without damaging the fat globules.

This is a very important feature for the treatment of cow’s goat’s milk or sheep’s milk. The wide working surface, the high centrifugal force and the expulsion extremely fast sludge guarantee a great efficiency of separation and cleaning. No recovery pumps are necessary because the skimmed product and the cream exit under pressure.

Cream separator with maintenance tools and spare parts

– Capacity: 1000L/H

– Make/Brand: Mora Marco

– Model/Type: Open Type

– Country of origin: Italy

– Oil level sight glass blasted for transmission

Download Complete Dairy Solution Brochure PDF

CONTACT US

- +44 1438316518

- +44789240418

- [email protected]