Home » Products » Dairy Farming Equipment » Rotary Milking Parlours

Rotary Milking Parlours

Comfort for the Cow, and Operator

To handle milking on large herd dairies, rotary milking parlours are an efficient use of space, labour and time. To create the most comfortable milking experience for the cow while on the rotary platform, each cow has their own bail area and feed trough, thus preventing bullying and creating a more relaxed environment for the cow.

With almost constant cluster application and less operator movement, the rotary parlour proves to be one of the fastest ways to milk cows. Incorporating Milk Metering with Pearson’s ProFarm Management System gives total control over the dairy herd.

Pearson Rotary Decks

The perfect combination of cow comfort, operator ease and durable construction.

Features of the Orbitor Rotary Deck

Industrial Roller System

A double I beam nylon roller system, both heavy gauge 180 x 75 I beams are fully galvanised, the bottom I beam is mounted on galvanised feet (one per unit) to give max strength & support. The nylon rollers are placed on the bottom I beam and connected with a carriage system. The top I beam is then positioned on the nylon rollers. This will be the moving beam. There are no bearings incorporated in any of the nylon rollers, giving one of the most industrial, long lasting roller systems on the market.

Deck Design

The concrete deck is forward sloping, this ensures all wash water runs forward into the drains and not back onto the operator.

Constructed from inner and outer structural nibs, A galvanised pan system is placed at the base of the deck for ease of concreting.

The table is reinforced with 10mm mesh & fibre concrete is poured to give max strength & long life to the rotary deck. The concrete table provides a quiet, strong platform for the animals to enter & exit comfortably.

Rotary Gland

The Pearson Rotary gland is constructed from the highest grade materials. It is manufactured from stainless steel with special nylon rings to minimise wear.

They can range from a 4 port gland supplying vacuum and milk, up to a 16 port gland for supplying teat spray, water and compressed air. The gland also supplies electrical power to the inside of the rotary allowing 11 separate connections.

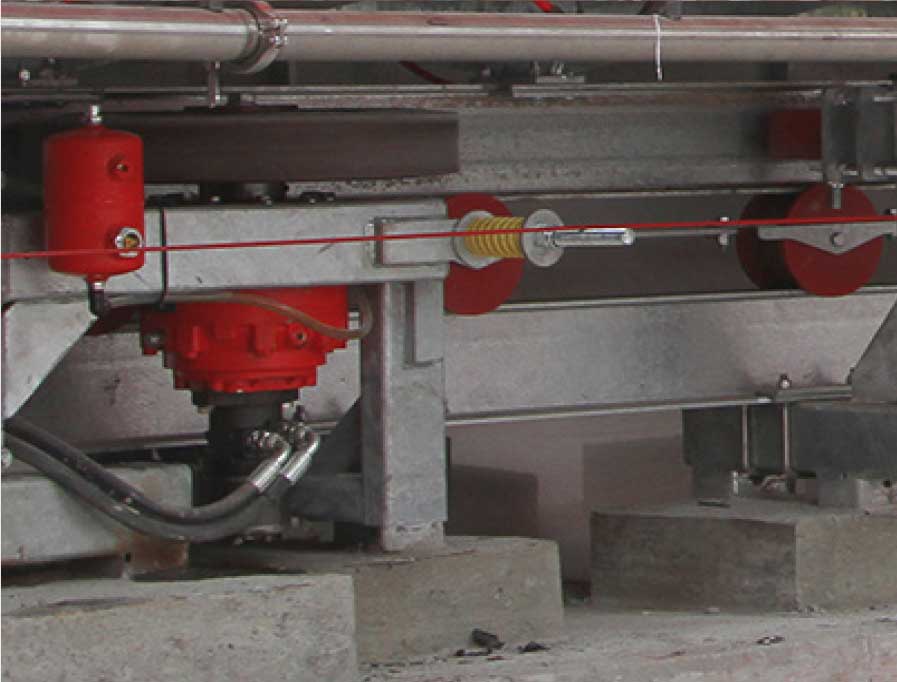

Drive System

The drive system which moves the rotary platform can be a hydraulic power system with electronic changeover valves or a full Electric drive system. Mounted under the table are the gear boxes with large drive wheels attached to move the table. If a power failure should occur, The Hydraulic power system comes with quick couplings to connect to a tractor to rotate the table allowing the cows to exit the platform.

Rotary Control Panel

The control panel activates the forward, stop and reverse functions, the table is equipped with a number of safety sensors to pause and start the table depending on cow movement at the exit and entrance points. From this panel you can control, seperate systems such as auto teat sprayers, crowd gates, cluster washers, etc.

Space Saving, Simple Design.

TP195 Stall Divider

Construction & Design

The bail is constructed of heavy duty black steel pipe and is then hot dipped galvanised giving a very durable robust bail unit. There is a stainless steel front cover mounted to the bail unit that holds the control unit or indicator display in place. The bail dividers are constructed from two heavy gauge box sections, the bottom one of the two houses the stainless steel manifold for milk and pulsation pipes. Using these materials reduces the amount of rubberware per unit and greatly reduces yearly service costs. It is a narrow bail design to allow more units within the space available.

The jetter cups are incorporated into the bail for easy and fast attachment and detachment.

Comfort

The bail unit has been designed with round and curved lines to allow comfort to the cows entering and exiting the units. The low height of the bail allows a more comfortable, easier entry onto the deck and gives a faster more relaxed exit off the rotary allowing the cow lift her head over the bail while reversing.

If feeding on the rotary, the head dividers prevent cows poaching and the stall dividers prevent pushing and bullying, this creates a comfortable environment for both the cow and operator.

Technology

All Pearson rotary bail units can be installed with a basic cluster remover and upgrade through the years to the Vision Global LED system for total farm and parlour management.

Download Rotary Milking Parlours Brochure PDF

CONTACT US

- +44 1438316518

- +44789240418

- [email protected]