Home » Products » Dairy, Food & Beverage » Milk Cooling Tank

Milk Cooling Tank

STI GB LIMITED, part of the British group designs and manufactures processing equipment for dairy, fruit juices and beverage industries. We can supply single machines as well as complete processing solutions (including turnkey plants), customized according to the specific requirements of each customer.

Milk cooling tank with cooling unit

The tank, double walled with insulation, fixed/attached with stirrer, control panel, manual CIP and individual cooling unit (all mounted as a complete unit)

Milk cooling tank with complete refrigeration unit

Capacity: 2000L, Model/Type: OPEN

The tank, double walled with insulation, fixed/attached with stirrer, control panel, manual CIP and individual cooling unit (all mounted as a complete unit)

Every dairy farm is required to have a milk cooling tank. Immediately after the milk is derived from the livestock using the milking machinery it has to flow into a storage tank where its temperature needs to be lowered to and maintained at 4°C.

What is a milk cooling tank made of – A milk cooling tank, also known as a bulk milk cooler, consists of an inner and an outer tank, both made of high-quality stainless steel AISI 304.

Attached to the inner tank is a system of plates and pipes through which the refrigerant fluid/gas flows. The refrigerant withdraws heat from the tanks content (e.g. milk).

Capacity: 2000L

The milk receiving tank will be design to capable of cooling fresh milk from +36°C to below +4°C and maintain cooling temperature at +4°C, cooling unit mounted on same frame of the tank and each milk cooling tank has one cooling unit individually.

Every cooling tank come with a condensing unit which circulates the refrigerant and conveys the withdrawn heat to the air. The space between the outer tank and the inner tank is isolated with polyurethane foam. In case of a power failure and an outside temperature of +36° C, the content of the tank will warm up only +1°C in 24 hours. To sacilitate an adequate and rapid cooling of the entire content of a tank, every tank is equipped with at least one agitator. Stirring the milk ensures that all milk inside the tank is of the same temperature and that the milk maintains homogene.

TECHNICAL FEATURES:

➤ Capacity of the each tank: 2000L

➤ The milk cooling tank will be design for capable of cooling fresh milk from +36°C to below +4°C and maintain cooling temperature at +4°C cooling unit mounted on same frame of the tank and each milk cooling tank has one cooling unit individually.

➤ Every cooling tank come with a condensing unit which circulates the refrigerant and conveys the withdrawn heat to the air. The space between the outer tank and the inner tank is isolated with polyurethane foam. In case of a power failure and an outside temperature of +36°C, the content of the tank will warm up only +1°C in 24 hours. To facilitate an adequate and rapid cooling of the entire content of a tank, every tank is equipped with at least one agitator. Stirring the milk ensures that all milk inside the tank is of the same temperature and that the milk maintains homogene.

The tank double wall with insulation, fixed/attached with a stirrer, Control panel manual CIP, and individual cooling unit all mounted as a complete unit.

➤ Every dairy farmer is required to have a milk cooling tank. Immediately after the milk is delivered from the livestock using the milking machinery it has to flow into a storage tank where its temperature needs to be lowered to and maintained at 4°C.

➤ What is a milk cooling tank made of: A milk cooling tank also known as a bulk milk cooler consists of an inner and an outer tank both made of high-quality stainless steel AISI 304.

➤ Address to the inner tank is a system of plates and pipes through which the refrigerant fluid/gas flows. The refrigerant withdraws heat from the tank content (e.g milk)

TECHNICAL SPECIFICATIONS MANUFACTURE:

➤AISI 304 stainless steel inner tank and outer casing.

➤ Total primary Trapcold™™ laser welded evaporator surface with maximum yield.

➤ Very thick eco-friendly and performing insulation by polyurethane foam.

➤ DN50 outlet-butterfly valve included.

➤AISI 304 stainless steel arm.

➤ Millimeter stainless steel. dip-stick with conversion-table in litres for the measurement of milk-level.

COOLING SYSTEM:

➤ Non-icing cooling even with low filling level.

➤ Direct expansion.

➤ R404A refrigerating fluid for all models.

➤Stainless steel cover.

High and low pressure switches.

➤ Compact and easy to install.

ELECTRIC SYSTEM:

➤FIPO 3 electronic milkcontroller.

➤ Milk temperature check and display.

➤ Stirring program. Thermal protection for threephase compressors as well as compressors’ inner protection.

➤ Electrical feeding cables with standardised plug (male).

➤ 230V 50HZ single-phase feeding or 400V three-phase feeding 50HZ + neutral.

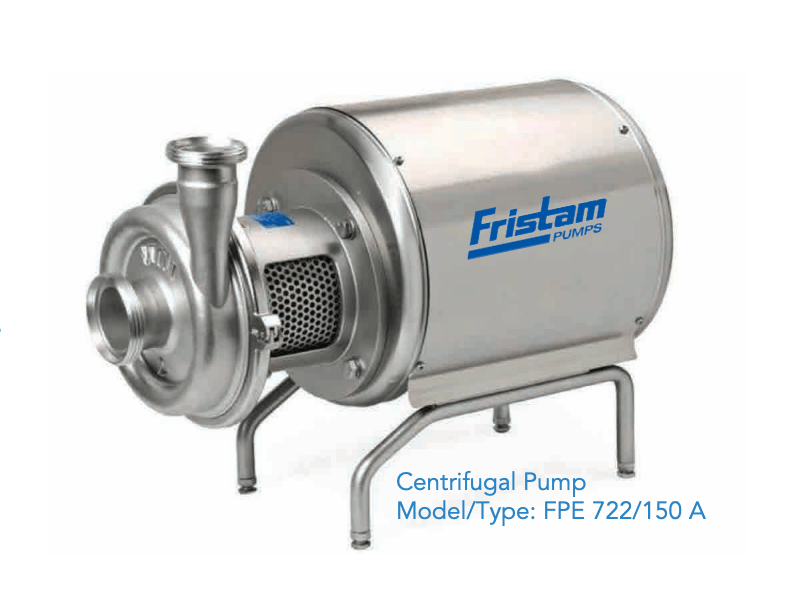

Centrifugal Pump

Centrifugal pump (for transfer of fresh milk from milk cooling tank to balance tank)

Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.

– Sanitary type mechanical seal.

– Sanitary design, suitable for dairy industry

– The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections. 380-400VAC, 50 Hz, 3 ph. (stabilized)

– Capacity:1000L

– Make/Brand: FRISTAM

– Model/Type: FPE722/150 A

– Country of origin: GERMANY

Electric control panel for suitable operation of milk cooling tank.

CENTRIFUGAL PUMP: (for transfer of fresh milk from milk cooking tank to balance tank

➤ Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316. properly finished, to ensure easy and accurate cleaning.

➤ Sanitary type mechanical seal.

➤ Sanitary design, suitable for dairy industry.

➤ The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections.380- 400VAC, 50 Hz, 3 ph. (stabilized)

➤ Capacity: 2000L/H

➤ Make/Brand: FRISTAM

➤ Model/Type:FPE722/150A

➤ Country of Origin: Germany

➤ Electrical control panel for suitable operation of milk cooking tank.

MILK RECOMBINATION UNIT

MILK RECOMBINATION UNIT with push button control panel comprising following accessories placed on frame.

COMPLETE MIXER BLENDER:

Supported by a base frame, a self-priming centrifugal positive displacement pump is connected to a Fristam shear pump. From a funnel the powder is drawn directly into the fluid product stream and then homogenised. An ergonomically designed table facilitates manual powder feeding.

➤ Capacity of the centrifugal pump: 10000L/H

➤ Make/Brand: FRISTAM

➤ Model/Type: FPE712/120 A

➤ Country of origin: Germany

Complete Mixer Blender:

✔ Make/Brand: EASY MIXER

✓ Model/Type: EZY 50

Country of origin: United Kingdom

CENTRIFUGAL PUMP

The centrifugal pump used for powder mixing will be placed on horizontal / vertical position of conical hauler with 50 kg capacity of milk powder at any time:

➤ Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.

➤ Sanitary type mechanical seal.

➤ Sanitary design, suitable for dairy industry.

➤ The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections.380-400VAC, 50 Hz, 3 ph.

(stabilized

➤ Capacity: 8000L/H

➤ Make/Brand: FRISTAM

➤ Model/Type: FPE712/115A

➤ Country of Origin: Germany

BUFFER TANK

BUFFER TANK (each tank delivered inclusive of the following accessories: air vent, CIP turbine, SS ladder, digital thermometer with paddle type agitator, capacity minimum 2,000L each)

BUFFER TANK CONSIST OF:

Entirely manufactured with STAINLESS STEEL AISI 304, capacity 2000L each equipped with:

✓ level control

✓ milk inlet valve

✓ water inlet valve

✓ Washing sphere

✓ Hermetic cover

CENTRIFUGAL PUMP

CENTRIFUGAL PUMP (circulation of water for mixing powder) with SS cover and placed on SS frame.

Fristam PUMPS

CENTRIFUGAL PUMP

➤ Any part which comes in contact with the product as well as all the main components are manufactured in STAINLESS STEEL AISI 316, properly finished, to ensure easy and accurate cleaning.

➤ Sanitary type mechanical seal.

➤ Sanitary design, suitable for dairy industry.

➤ The pump is equipped with heavy duty motor, IP65, with suitable arrangements for cable connections.380-400VAC, 50 Hz, 3 ph. (stabilized

➤ Capacity: 8000L/H

➤ Make/Brand: FRISTAM

➤ Model/Type: FPE712/115A

➤ Country of origin: Germany

Download Complete Dairy Solution Brochure PDF

CONTACT US

- +44 1438316518

- +44789240418

- info@stigblimited.com